Mat Bowtell of FREE 3D Hands creating joy with his altruism and engineering expertise

By Aussie Hands

‘When I was 9 years old, my younger brother had an electric water pistol which I decided to pull apart, make a few modifications and put back together. The end result was brilliant – the water went three times as far and with a lot more force – and I will never forget the smile on my younger brother’s face.’

This moment sparked Mat’s interest in engineering and was when he realised that he got more enjoyment making things for other people than for himself.

Growing up in a small, tight-knit community, Mat didn’t know anyone with a hand difference but one of his friends had a rare genetic condition called FOP (fibrodysplasia ossificans progressiva) where skeletal muscle and connective tissue gradually turn to bone. His friend needed a $40k wheelchair but had to fight to get funding, so the local community banded together, held fundraisers and managed to provide 75% of the cost. Mat’s belief in communities coming together to help others was triggered.

Mat went on to study Engineering at Monash University and after receiving a scholarship to study mechatronics in Japan, he had the opportunity to try on a one-million dollar bionic arm. However, he also felt sadness that something like this wouldn’t be affordable or accessible to most people who needed it. By combining his altruistic nature and engineering skills, Mat began his mission to develop low cost hands and assistive devices using 3D printing technology.

‘My involvement with Aussie Hands began about 4 years ago when Julie McNally (former Executive Officer) got in touch after seeing me in a news interview. I joined the Aussie Hands Facebook group, attended some events and immediately clicked with the group. I really value my relationship with Aussie Hands whose members are vital in helping to design, test and improve the various devices we make,’ said Mat

This feedback was crucial for the continuous improvement of the Kinetic Hand design, which was released open-source (allowing software to be freely used, modified, and shared) in October 2020 and was downloaded over 1,750 times around the world in the first three weeks. The design now incorporates features to assist others to easily print their own hands. It is accompanied by an extensive print and assembly manual to guide people with beginners to advanced knowledge. Anyone can replicate what Free 3D Hands do.

Mat also shares his designs for free under an open-source licence so anyone, anywhere can create their own hand. A great example is e-NABLE – a global community of volunteers who have delivered free 3D printed hands and arms to an estimated 8,000 recipients. A young boy called Filip, who lives in Poland, is now using one of Mat’s Kinetic Hands, which was made for him by an e-NABLE volunteer in his home country.

The existing 3D hands are body powered using wrist movement. Mat is now working on creating a low-cost Bionic Arm that uses muscle pattern recognition to operate the hand and is also looking at a simpler, elbow powered arm. If anyone would like to help him test these devices, please get in touch via the Free 3D Hands website to express your interest or submit an application form.

Most health professionals generally use their experience to determine what children with a hand difference want or need, but if you ask the kids themselves, they can often provide greater detail which leads to a richer, more targeted solution. Mat couldn’t agree more and remembers when he was an engineer at Toyota, they were reminded to go to the source of the problem. This means not trying to solve it from behind a desk but talk to and understand what those people want to achieve.

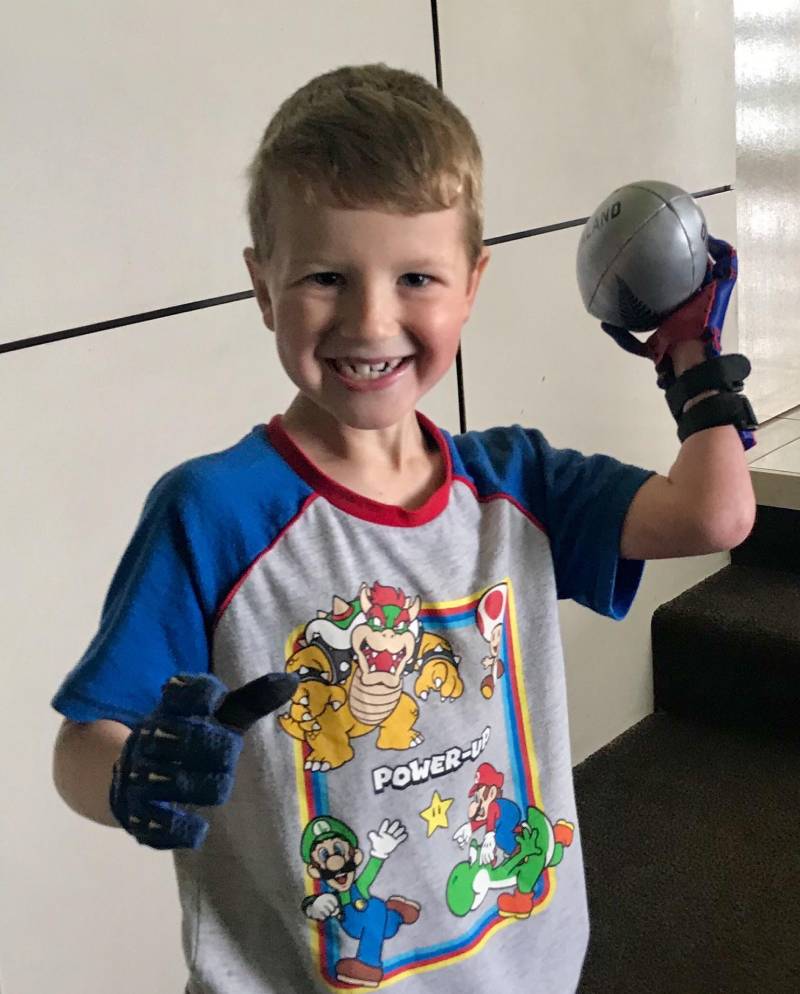

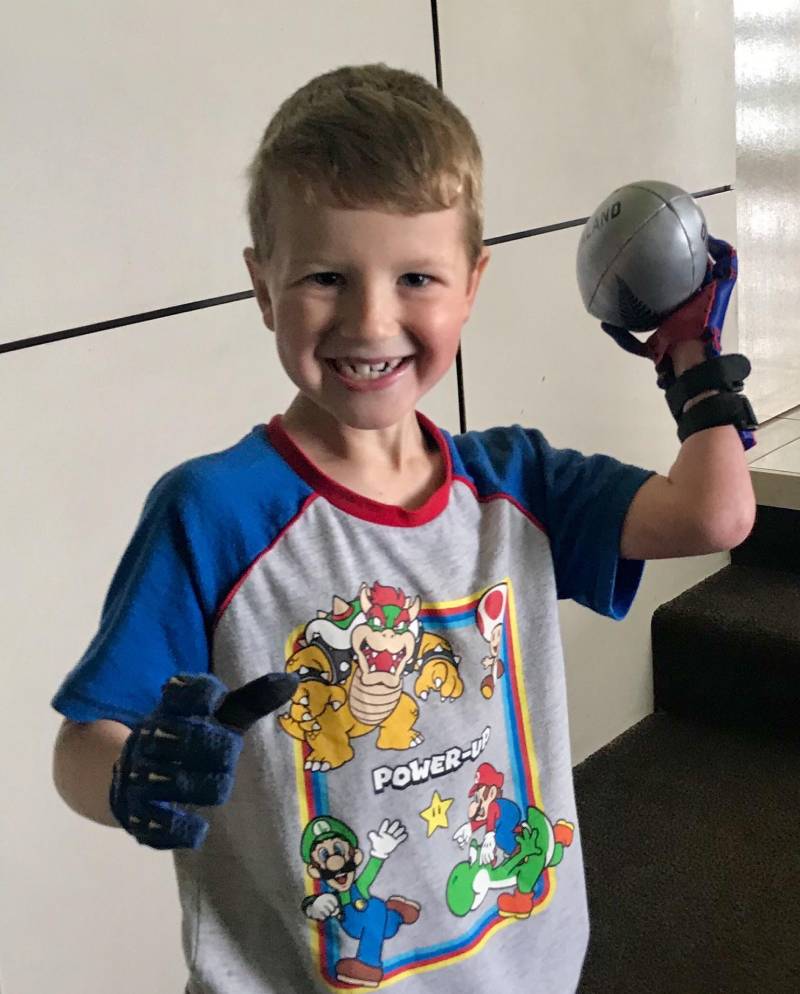

Mat’s designs and adjustments have further developed by getting involved with the Aussie Hands community and learning that people may not necessarily want a hand, but for example a skipping rope attachment, tennis ball thrower or something to help them play the piano.

Followers of Free 3D Hands will also know that they came to the Australian Government’s rescue when health professionals badly needed a reliable supply of PPE to cope with the COVID-19 pandemic. Anticipating a raw materials shortage in Australia, Mat immediately set about securing the necessary materials to begin producing face shields. Thanks to the flexibility of 3D printing technology, Free3D Hands was able to very quickly switch from making hands to manufacturing PPE. Using a combination of community and government funding, they were able to produce 6000 face shields and provide them for free to frontline workers – a fantastic and life-saving contribution.

Now that the demand for PPE has been met, Mat and the team are excited to continue devoting themselves to their passion of creating hands. ‘We aim to become a world leading design hub which focuses on development rather than becoming a larger scale manufacturing operation. We want to become a centre for collaboration and the sharing of ideas to help people with limb differences achieve all they can,’ added Mat.

Most of us take it for granted that we’ll have a constant power supply, though this wasn’t always the case for Mat and his team. Losing power for just 1 second means the 3D printers immediately fail, and any parts mid-print have to be discarded. This leads to wastage and longer wait times for recipients as the parts need to be reprinted from scratch. Thanks to support from Tesla, RACV Solar and Fronius, Free 3D Hands now have 109 solar panels on their factory roof and an uninterrupted power supply which means the printers have a constant battery backup. The factory is also now powered by the sun!

The hands themselves are mostly made from a material called PLA (polylactic acid) which is derived from corn starch, is biodegradable and non-toxic. The hands have no electrical components so they can be used around water, in high humidity and be exposed to the general mess that kids make! Though it was discovered that the hands are not ‘dog proof’, they are remarkably strong and each component has been designed with longevity in mind. Most recipients grow out of their device before they wear it out.

Mat draws inspiration from the late Fred Hollows, who trained doctors in their own countries to perform eye surgery and thereby restored sight to thousands more people than if he’d only used his own skills to operate. Nikola Tesla is another important figure, whose goal was to provide free energy. They all had the intention of leaving the world a better place and sharing their ideas with humanity.

Mat wants to keep putting a smile on children’s faces and we know he’s successfully managed that with many of the Aussie Hands family.

‘We’ve lost count of how many hands and assistive devices have gone out the door, but it’s not about the numbers, it’s about manufacturing joy,’ Mat concluded.

Thanks to Mat for sharing his story and working with Aussie Hands in supporting people with a hand difference . You can help Aussie Hands continue to support its work by making a donation.